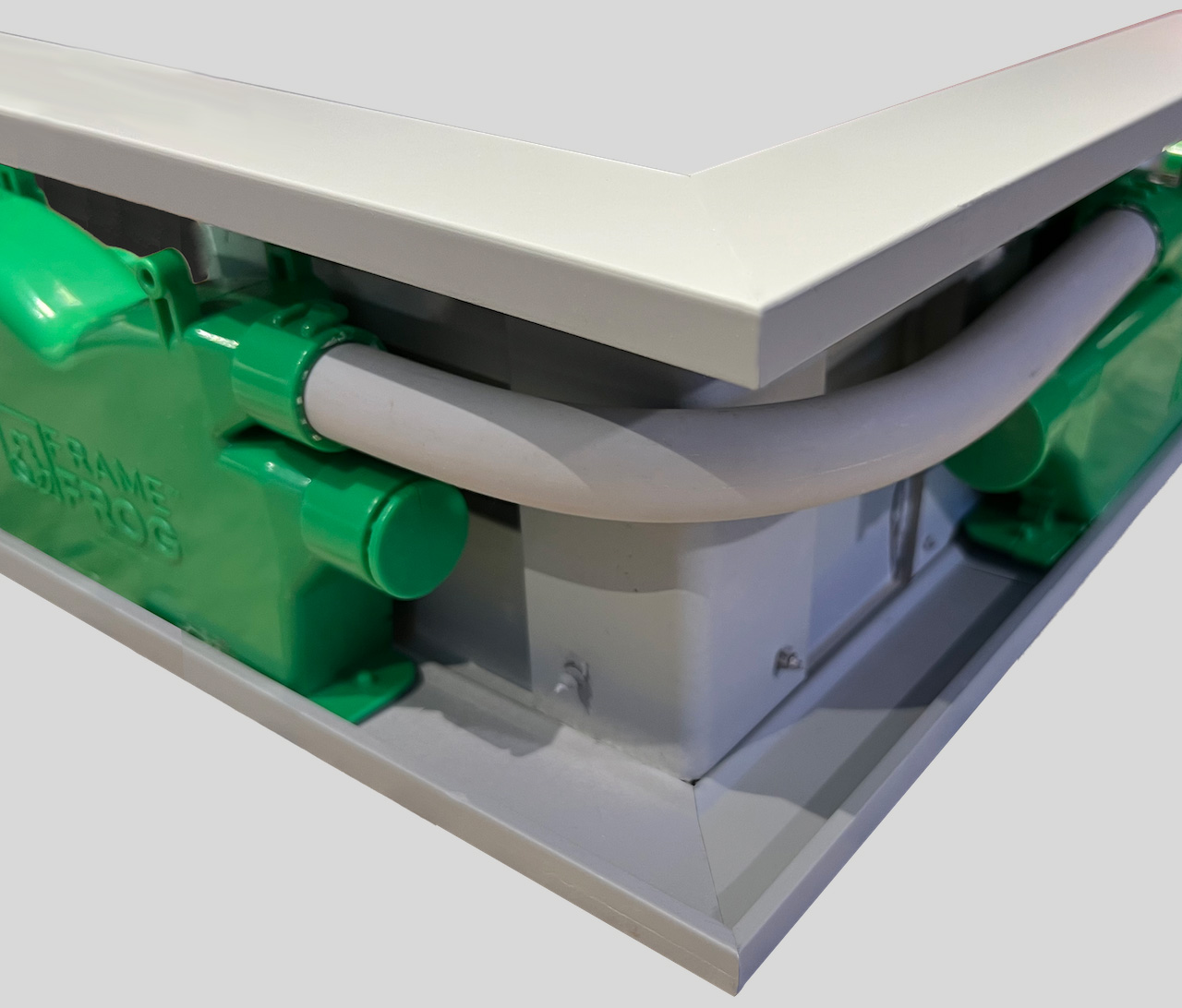

We’re excited to announce that Frame Frog is now available for FRP (fiberglass reinforced plastic) frames. This expansion brings our proven wiring pathway solution to industries and environments where traditional hollow metal frames simply won’t hold up and where clean, reliable access control installation has been especially challenging.

Expanding Frame Frog’s Compatibility

For years, Frame Frog has simplified access control wiring in hollow metal frames by creating a defined, intentional pathway that eliminates guesswork and rework. Now, we’re bringing that same reliability to FRP applications.

This expansion responds to growing demand from contractors and facility teams working in healthcare facilities, research laboratories, food processing plants, pharmaceutical manufacturing, and any environment where corrosive conditions, strict hygiene requirements, or moisture exposure make FRP frames the only viable choice.

Whether you’re working with steel or fiberglass door frames, Frame Frog’s core mission remains the same: create a structured wiring pathway that works from day one and supports future needs without compromise.

Why FRP Frames Create Wiring Challenges

FRP frames are engineered for extreme durability in harsh environments. They resist corrosion, withstand frequent washdowns, and meet strict sanitation standards. But they’re rarely designed with wiring accessibility in mind. The result? Installers face a set of unique challenges:

Limited internal space makes clean routing difficult. Unlike hollow metal frames with predictable internal dimensions, FRP frames often have minimal cavity space and irregular internal geometry. There’s simply less room to work with.

Field drilling becomes the default—and brings problems with it. Without a pre-planned pathway, installers are forced to drill, notch, or cut FRP material on-site. This leads to inconsistent results from opening to opening, increases the risk of damaging the frame’s structural integrity or finish, and often results in exposed conduit or surface-mounted wiring that looks unfinished and creates maintenance headaches down the road.

There’s no standardized pathway, so every installation is custom. When each door requires a unique solution, coordination between trades breaks down. The electrician roughs in conduit one way, the frame installer preps differently, and the access control technician has to improvise during final installation. The lack of a consistent approach creates delays, confusion, and costly rework.

For facility managers, these improvised installations create long-term problems. When access control hardware needs service or replacement years later, technicians face the same challenges all over again, often with even less information about how the original wiring was routed.

How Frame Frog Solves the Problem for FRP Frames

Frame Frog for FRP frames provides what’s been missing: a structured wiring pathway designed specifically for fiberglass applications. Instead of drilling, guessing, or improvising in the field, installers now have a clear, reliable solution that integrates seamlessly with FRP frame construction. In fact, Frame Frog is now the only method available for installing wiring junction boxes within FRP frames.

The system supports all standard access control and low-voltage wiring needs—card readers, electric strikes, mag locks, request-to-exit devices, door position switches, and power transfers—without requiring ad-hoc field modifications that compromise the frame or the installation quality.

Frame Frog for FRP delivers the same benefits our customers have come to expect from our hollow metal solutions:

Cleaner installations. Wiring is routed through a dedicated pathway rather than surface-mounted or awkwardly concealed. The result is a professional finish that meets the aesthetic standards of modern facilities.

Better coordination between trades. Electricians, frame installers, and access control technicians all work from the same specification. There’s no ambiguity about where conduit should terminate or how wiring will route through the frame. Everyone knows the plan, and the plan works.

Reduced rework and inspection risk. When the pathway is engineered and tested rather than improvised, there’s no need to fix mistakes after installation. Inspections go smoothly because the system is designed to meet code from the start.

For FRP applications, these benefits are especially valuable. In environments where frames must meet strict sanitation, chemical resistance, or moisture protection standards, any field modification creates risk. Frame Frog eliminates that risk by building the pathway solution into the frame from the beginning.

Contact us to learn more about Frame Frog for FRP frames or request product specifications and installation guidelines for your upcoming build.